ʻO ke ʻano o ka calendering floor PVC kahi kaʻina hana kūpono a hoʻomau, kūpono loa ia no ka hana ʻana i nā ʻāpana ʻāpana homogeneous a me ka permeable (e like me ka pāʻoihana homogeneous permeable flooring). ʻO kāna kumu, ʻo ia ka hoʻopololei ʻana i ka PVC i hoʻoheheʻe ʻia i loko o kahi ʻāpana lahilahi ʻaʻahu ma o kahi kalena multi-roll, a laila hoʻomāalili i ke ʻano. Eia nā ʻanuʻu kikoʻī a me nā wahi mana ʻenehana koʻikoʻi:

I. Kaʻina Kalena

Hoʻomaʻamaʻa mua ʻana i nā mea kanu > ʻO ka hui ʻana wela kiʻekiʻe, ka hui ʻana a me ke anuanu, ka hui ʻana o loko a me ka plasticizing, ka hui ʻana a me ka hānai ʻana.

ʻEhā ʻōwili calendering, embossing/laminating, hoʻoluʻu a hoʻohua, ʻokiʻoki a me ka wili.

II. Kaʻanuʻu-ma-kaʻanuʻu hana kī kī a me ka 'ike loea

1. Hoʻomaʻamaʻa mua a me ka hui ʻana

Hoʻohui ʻia (Laʻana): - PVC resin (S-70 type) 100 mau ʻāpana, - Plasticizer (DINP/environmentally ester ester) 40-60 ʻāpana, - Calcium carbonate filler (1250 mesh) 50-80 mau ʻāpana, - Heat stabilizer (calcium zinc composite) 3-5 mau ʻāpana, - Lubricant-0. (titanium dioxide/pauma kala inorganic) 2-10 ʻāpana

Kaʻina hui ʻana*:

Hoʻohui wela: Mea hoʻohui kiʻekiʻe (≥1000 rpm), wela i 120 ° C (10-15 mau minuke) e hiki ai i ka PVC ke komo i ka plasticizer; ʻO ka hui ʻana o ke anu: ʻoluʻolu a hiki i lalo o 40 ° C (e pale i nā ʻōpala), ka manawa hui ʻana ≤ 8 mau minuke.

2. Plasticizing a hānai

- Mea hoʻohui i loko: Ka wela 160-170 ° C, Pressure 12-15 MPa, Manawa 4-6 mau minuke → Hoʻokumu i kahi hui like ʻole;

Mea Hoʻohui Wehe: Mālua-roll wela 165±5°C, Roller Gap 3-5 mm → ʻOki i loko o nā ʻāpana no ka hānai mau ʻana i ka kalena.

3. ʻEhā-roller Calendering (Kaʻina Hana)

- Nā ʻenehana koʻikoʻi:

- ʻO ka Laki ʻana o ka Roller Speed: 1#:2#:3#:4# = 1:1.1:1.05:1.0 (no ka pale ʻana i ka hōʻiliʻili mea);

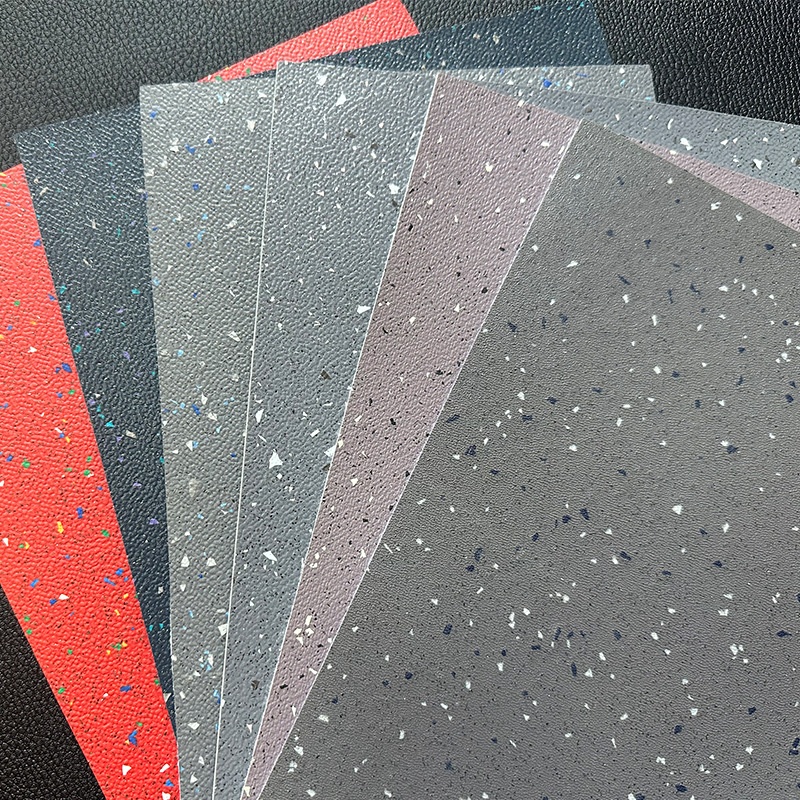

- Uku Uku Kiʻekiʻe: Hoʻolālā ʻia ʻo Roller 2 me ka lei aliʻi 0.02-0.05mm e hoʻopau i ka deformation bending thermal. 4. Hoʻoponopono i ka ʻili a me ka Lamination

Embossing: Embossing roller (silicone/steel) wela 140-150 ° C, kaomi 0.5-1.0 MPa, ka wikiwiki e like me ka laina calendering;

Lamination Substrate (Kūpono): ʻO ka moena fiber aniani/ʻaʻahu ʻole i ulana ʻia, i hoʻomaʻamaʻa mua ʻia (100°C), ua laminated me ka PVC hehee ma ka roller #3 e hoʻonui ai i ke kūpaʻa ʻana.

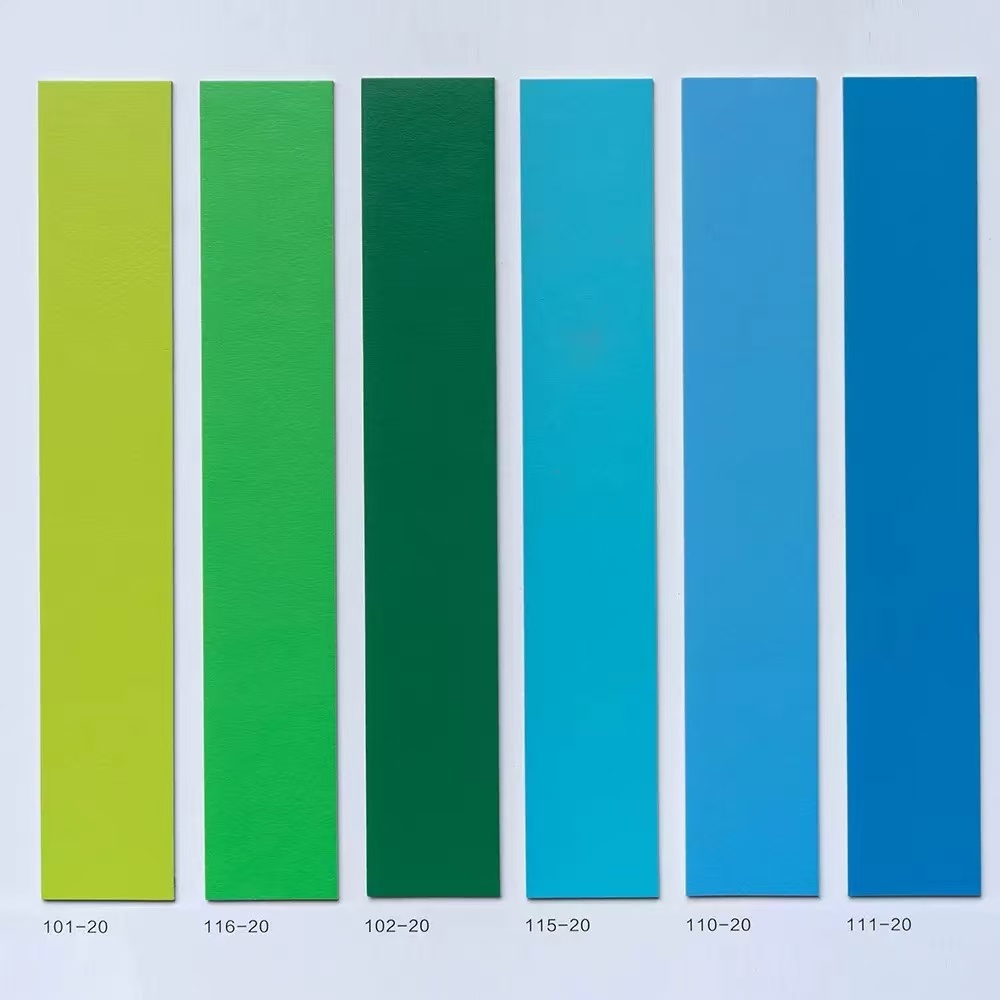

5. ʻO ka hoʻoluʻu a me ke ʻano

ʻEkolu-ʻanuʻu hoʻoluʻu wela wela:

Ka Mana Manawa: ʻO ka hoʻoluhi ʻana o ka makani 10-15 N/mm² (no ka pale ʻana i ke anuanu a me ka deformation).

6. ʻOki a me ka wili

- Ke Ana Mānoanoa Online Laser: Hoʻoponopono ka manaʻo manaʻo maoli i ka ʻāpana wili (pololei ± 0.01mm);

- Hoʻokiʻoki 'akomi: Ka laula ʻōpala ≤ 20mm, hana hou ʻia a pelletized no ka hoʻohana hou ʻana;

- Ka makani: ʻO ka wili mau ʻana o ke kikowaena kikowaena, ʻo ke anawaena o ka ʻōwili Φ800-1200mm. III. Nā pilikia a me nā hoʻonā kaʻina

1. Mānoanoa like ʻole. Ke kumu: ʻO ka hoʻololi ʻana o ka wela o ka Roller > ±2°C. Pane: Hoʻopaʻa-Loop Thermal Oil Temperature Control + Close-Drilled Roller Cooling.

2. Ke kinoea ʻili. Ke kumu: ʻAʻole lawa ka hui ʻana i ka Degassing. Pane: E hoʻomāmā i ka Mixer Kuloko (-0.08 MPa).

3. Nā māwae Edge. Ke kumu: ʻO ka hoʻoluʻu nui ʻana/ka haʻalulu nui. Pane: E ho'ēmi i ka ikaika hoʻoluʻu mua a e hoʻohui i kahi wahi hoʻomaha mālie.

4. Make Pattern. Ke kumu: ʻAʻole lawa ka hoʻoheheʻe ʻana i ka Roller Pressure. Pane: E hoʻonui i ka Hydraulic Pressure i 1.2 MPa a hoʻomaʻemaʻe i ka Roller Surface.

IV. ʻO nā kaʻina hana i hoʻomaikaʻi ʻia i ke kaiapuni

1. Hoʻololi Paʻa Paʻa Lead-Free:

- Calcium-Zinc Composite Stabilizer + β-Diketone Synergist → Passes EN 14372 Migration Test;

2. Kaiapuni Friendly Plasticizer:

- DINP (Diisononyl Phthalate) → Cyclohexane 1,2-Dicarboxylate (Ecoflex®) Hoʻemi i ka Ecotoxicity.

3. Hoʻopalapala ʻōpala:

- Ka ʻohi ʻana i nā ʻōpala → Hoʻohui ʻia me nā mea hou ma ka ratio o ≤30% → Hoʻohana ʻia i ka hana papa kumu.

V. Calendering vs. Extrusion (Hoʻohālikelike Noi)

Huahana Huahana: Ka papahele homogeneous perforated/Multi-layer composite, Multi-layer co-extrusion (pahu pale ʻaʻahu)

Mānoanoa: 1.5-4.0mm (Pono ± 0.1mm), 3.0-8.0mm (Pono ± 0.3mm)

Hoʻopau i ka ʻili: Kiʻiʻoniʻoni kiʻekiʻe/Precision embossing (hoʻopiʻi ʻana i ka hua lāʻau), Matte/Rough texture

Nā noi maʻamau: ʻO ka papahele homogeneous perforated i loko o nā halemai a me nā keʻena hana, SPC e pili ana i ka papahele no nā hale.

Hōʻuluʻulu manaʻo: Aia ka waiwai nui o ke ʻano calendering i "ka pololei kiʻekiʻe" a me ka "kiʻekiʻe kūlike"

- Nā Pono Hana Hana:

- Ka hoʻomalu ʻana i ka wela o ka ʻōwili pololei → Koefficient hoʻololi mānoanoa <1.5%;

- Ka hoʻopili ʻana i ka laina a me ka lamination → Loaʻa i nā hopena ʻike pōhaku/metala;

- Nā huahana pili:

ʻO ka papahele PVC perforated homogeneous me nā koi kūpaʻa kiʻekiʻe (e like me ka moʻo Tarkett Omnisports);

- Nā koho hoʻonui:

- Mana Manaʻo: AI-powered dynamic roller gap adjustment (real-time mānoanoa manaʻo);

- Hoʻihoʻi ʻana i ka ikehu: Hoʻohana ʻia ka wela wai hoʻoluʻu no ka hoʻomaʻamaʻa ʻana i nā mea maka (e mālama ana i ka ikehu 30%).

> Nānā: Ma ka hana maoli, pono e hoʻoponopono ʻia ka mahana calendering a me ka wikiwiki o ka wili e like me ke ʻano fluidity (mea hoʻoheheʻe MFI = 3-8g/10min) e pale aku i ka hoʻohaʻahaʻa ʻana (ka helu melemele ΔYI <2).

Ka manawa hoʻouna: Iulai-30-2025